Polymer Processing Aids Masterbatch: Everything You Need To Know

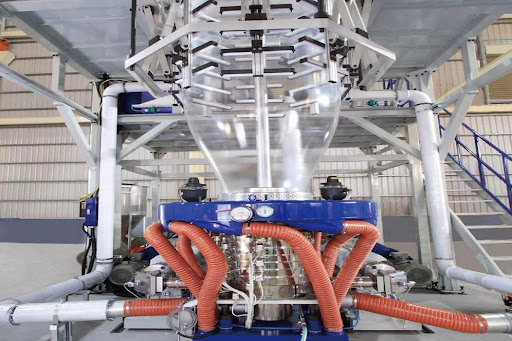

Polymers with macromolecular structures are designed to give very good properties for end products. But processing these polymers at very high throughputs and producing very thin films at a higher shear rate is very critical. Processing aids refer to several different classes of materials used to improve processability.

Polymer processing aids are always advised to be used by a well-dispersed Masterbatch route giving better effects in the end product applications.

Processing aids lower the surface friction of polyolefin (PO) films, allowing the film to be rapidly extruded and then shipped or stored in rolls.

Selection of the Right product-

Thousands of products are available in the market. But selecting the right product based on your application after communicating with our technical team is most important.

In addition to the thin film application, it can be used for several applications but the right product is selected based on factors like the final application, processing temperatures, shear rate, other ingredients added and also based on rheological properties of the Masterbatch.

The Most Significant Advantages of Polymer Processing Aids Masterbatch

Eliminate Melt Fracture

One of the common flow issues for polymer processing is melt fracture. This issue is mostly caused by the high stress exerted at the die exit. The roughness of the polymer surface can also exacerbate these issues, resulting in the distorting of the final product.

The final product can have a poor appearance and reduce its strength and other defects. Polymer processing aid Masterbatch can eliminate Melt Fracture and improve the quality of the product.

Reduce Die Build-Up

Die to build up is another problem you might face when processing polymer. Here the die build-up refers to the material deposit on the die exit. To avoid this situation, you will need a frequent stoppage to clean up the die and improve the product quality.

Note that this is a worse situation because it can take even days or weeks to clean once it gets worse. However, with the polymer Processing Aids Masterbatch, you can reduce or eliminate this issue.

Increase Output

When it comes to the processing or production of the polymer higher throughputs are always required.

With the polymer processing aids Masterbatch, you will be able to eliminate most of the issues that could slow or hinder the production & eliminate the issues like die build-up, melt fracture, and boosting efficiency, thereby guaranteeing an increased output during the polymer processing.

Other Benefits:

- More efficient conversion operations downstream: Films must slide easily against process equipment, and rolled films must unroll easily without sticking or blocking.

- Printability and adhesion: The additives used to decrease the friction of film and sheet ideally should not interfere with printing or adhesion on the plastic surface when it is required.

- Process cleanliness: Excess additives or fragments from the melt or solidifying resin must not build up on screen packs, dies, or processing equipment.

- Process flexibility: When problems with film processing occur, converters who can flexibly adjust their processing aid type or concentration stand to benefit.

- Low scrap: Given that 80% of a film’s cost can be tied to resin costs, a successful operation must use resin efficiently, minimizing waste or off-spec materials.

Kandui PPA Masterbatches also ensure the other key benefits like better transparency, Gloss smoothness & transparency, improved mechanical properties and gauge control.

Conclusion

The major benefits of the polymer processing aid Masterbatch are mentioned above.

With the help of this processing aid, you will be able to speed up the processing process without having problems like increasing temperatures,

Melt fracture, die to build up, and many other problems. These major benefits, it will also lead to other indirect benefits like reducing the cost of production and increasing the profit without sacrificing the quality of the product.